Shrink films have become a go-to option in the packaging market as the material not only helps protect the product but also represents it at the same time. There are various types of shrink films available and LDPE (Low-Density Polyethylene) shrink film is most in demand in the industry as it is very malleable, durable, and economical. Understanding the LDPE shrink film’s properties will help you in selecting the right packaging for the production, logistics, or retail if you are one of them. By knowing what the LDPE shrink film is and then can be used to identify its capabilities, the manufacturing process, the guest list, and the pros, cons, and other shrink film types that are available in the market for favorable comparison, your decision of the most suitable packaging material can be reached.

This in-depth tutorial not only breaks down what LDPE shrink film is but also explains how it can be of use in various industrial sectors, and what its advantages are with respect to the manufacturing process, besides the comparison with other types of shrink films.

What is LDPE Shrink Film?

Low-Density Polyethylene (LDPE) shrink film is a plastic that is able to change its shape and regain its original shape. Elasticity and flexibility shrink film is ideal for a variety of uses, one of which is product packaging, the film becomes firmly attached to the products after being exposed to heat. The quality LDPE films are well known for their impact-strength and the feature of stretchability, which makes them suitable for packing bulky or heavy things, even if they are not as clear as PVC or polyolefin films.

The film is created by mixing ethylene to create polyethylene that is used as the base material for the film. Afterwards it is melted, extruded, and then cooled down to form a thin sheet and finally stretched out, so that the molecular tension is created thus film can shrink when needed. The constricting of the film is done by the application of heat, heat tunnels, or heat guns triggering the retraction of the film, which now firmly wraps around the product to provide disturbance prevention and dust and water protection.

The LDPE shrinking film is the most common plastic film used in several industries whose products and services are food and beverage, logistics, and retail. The film is an excellent choice for the bundling of bottles, boxes, and mechanical parts and it is recyclable (plastic code #5), so it is more environment friendly as the packaging option for the same.

Properties of LDPE Shrink Film

LDPE shrink film is a material that has been given a set of physical and chemical characteristics which are very extraordinary, and these are the characteristics that make it an ideal packaging material. Here are the main ones:

- Low Density and High Flexibility

Low-density polyethylene is less heavy than other types of polyethylene products, which makes it more flexible and stretchable, so much that the application of heat is not necessary for wrapping products of various shapes.

- Clarity and Gloss

LDPE may not be as transparent as PVC or polyolefin shrink films, yet it does exhibit a bearable level of High transparency PET shrink film sleeve label and a shiny finish which would be all right for simple packaging.

- Excellent Impact and Tear Resistance

The outstanding feature of this type of film is its capability to resist a tearing impact as well as to provide the puncture resistance, and especially when the temperature is as low as freezing. The item is correctly designated for heavy-duty or high-impact uses.

- Shrink Rate

It usually has a medium shrinkage rate (of up to 40-60%), which is sufficient for the secure bundling and packaging of a wide variety of items.

- Waterproof and Chemical Resistance

This wrap is practically a barrier that enables the product to repel water, dirt, and certain chemical substances that would be the cause of the product’s corrosion.

- Eco-friendliness

This type of plastic is part of the plastic code #4 groups that can be recycled and make it environmentally friendly because the recycling of this type consumes less energy compared to the production from virgin materials. Besides this you can also read Health Benefits of Assam Tea Vs Darjeeling Tea in Table listed in our website.

Common Uses of LDPE Shrink Film

LDPE shrink film is a commonly employed plastic stretch film in a broad range of sectors, attributed to its flexibility. These include several ubiquitous examples:

- Bundling Products

Items that are to be transmitted can be put under minimal packaging using LDPE shrink film. For example, bottles, cans, or boxes of multiple items are frequently combined for this purpose.

- Industrial Packaging

The film is commonly used in industry for wrapping machinery parts, building materials, and hardware to protect them against dust and moisture.

- Food Packaging

Although not so much in constant touch with food, LDPE shrink film is employed as a means of secondary packaging in the food industry, entailing such operations as wrapping the cans or trays of bottled drinks with it.

- Retail Packaging

Mostly due to the low cost and good protective properties of this packaging material, retailers apply LDPE shrink film to consolidate the packaging of their products such as cosmetics, electronics, toys, and promotional packs.

- Pallet Wrapping

When distributing goods, LDPE shrink film, an integral material in logistics networks, is employed to ensure the stability of the pallets by wrapping them and consequently to minimize, or even eliminate the risk of the cargo being damaged during transportation.

How is LDPE Shrink Film Made?

The manufacturing of LDPE High shrink PET film is made through various stages one of them being:

- Polymerization

LDPE is produced by using a process in which ethylene gas is polymerized in a reactor at high pressure and temperature. At the end of this production, LDPE appears to have very low density and is flexible due to the branching of the polymer structure.

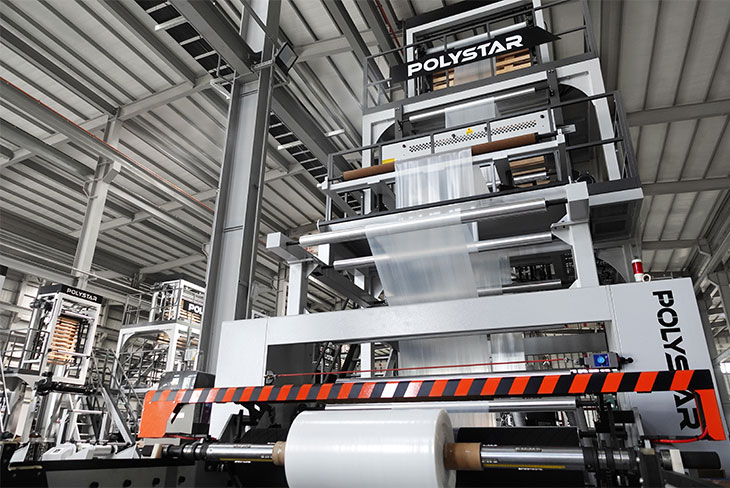

- Film Extrusion

The raw material is melted and then pushed through the die, so it could transform from a shape of globule to that of a tubular form. This process is called blown film extrusion. During this, the film is stretched and thinned by air, which also determines the film’s width and thickness.

- Cooling and Flattening

The blown film bubble is first of all cooled by air rings and then flattened between the rollers thus forming the film folds.

- Shrinking Properties

The film can experience the stretch effect due to pre-treating it, for instance, in the annealing stage or making adjustments in the extrusion phase to regulate the molecular orientation.

- Winding

Eventually, the film is rolled up for the future process of cutting and packaging.

Choosing the Right LDPE Shrink Film

When selecting LDPE shrink film, consider the following factors:

- Thickness (Gauge or Microns): Thicker films are better for heavier items.

- Width and Roll Size: Based on the size of the product to be wrapped.

- Shrink Temperature: Ensure compatibility with your heat tunnel or gun.

- Printing Requirements: Some applications require custom-printed shrink films.